At the end of last year, we took a significant step forward in enhancing our processing capabilities at our silica sand mine by installing the Linatex fluidised flat bottom classifier. This state-of-the-art equipment has already started to revolutionise our operations, allowing us to produce a higher quality product that better meets the needs of our customers.

What is the Linatex Fluidised Flat Bottom Classifier?

The Linatex fluidised flat bottom classifier is a sophisticated piece of equipment designed to improve the quality of our silica sand. It operates by using a dense fluidised bed of near-size sand to separate lighter materials from heavier fractions. This process effectively removes fines and organic material from the coarse sand, resulting in a cleaner and more consistent sized product.

Why did we choose to install the Classifier?

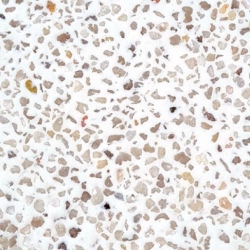

At Sunstate Sands, we dry-dig our natural high purity white quartz sand from the land adjacent to the dunes of the beach where there is natural vegetation. The first part of our process is to remove this vegetation and to rehome it to where we have just mined. This is the best-practice method as recommended by the environmental agencies as it gives a very successful strike-back rate and promotes fast tree growth returning it to its former beauty. However, after removing the vegetation, there are still roots running as deep as 4-6m below where the trees were and they are chopped up during the excavation process. When these roots are added (within the sand) to the wash plant they take on a similar weight of the sand and hence get sorted and deposited onto the various stockpiles with the sand, although they are usually concentrated in the coarser materials. To help remove this small root matter, we’ve added the additional process of the Linatex Fluidised Flat Bottom Classifier.

How Does It Work?

The operation of the classifier is both innovative and efficient. A mixture of water and sand (slurry), enters the top of the unit through a central feed well. Water is injected into the system via a chamber, using specialised nozzles to create an upward rising current. This current establishes a zone of suspended solids, where the separation occurs.

In this suspended state, solids of varying sizes are differentiated at the cut point, the size fraction at which separation happens. The finer granules of sand are floated over a weir and removed, while the larger granules discharge from the bottom of the classifier. This process ensures that the end product is not only better sized but also significantly free of organic materials.

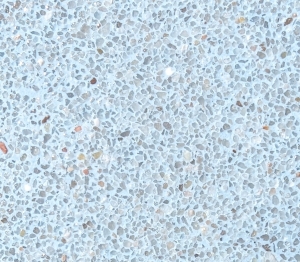

Enhancing Product Quality

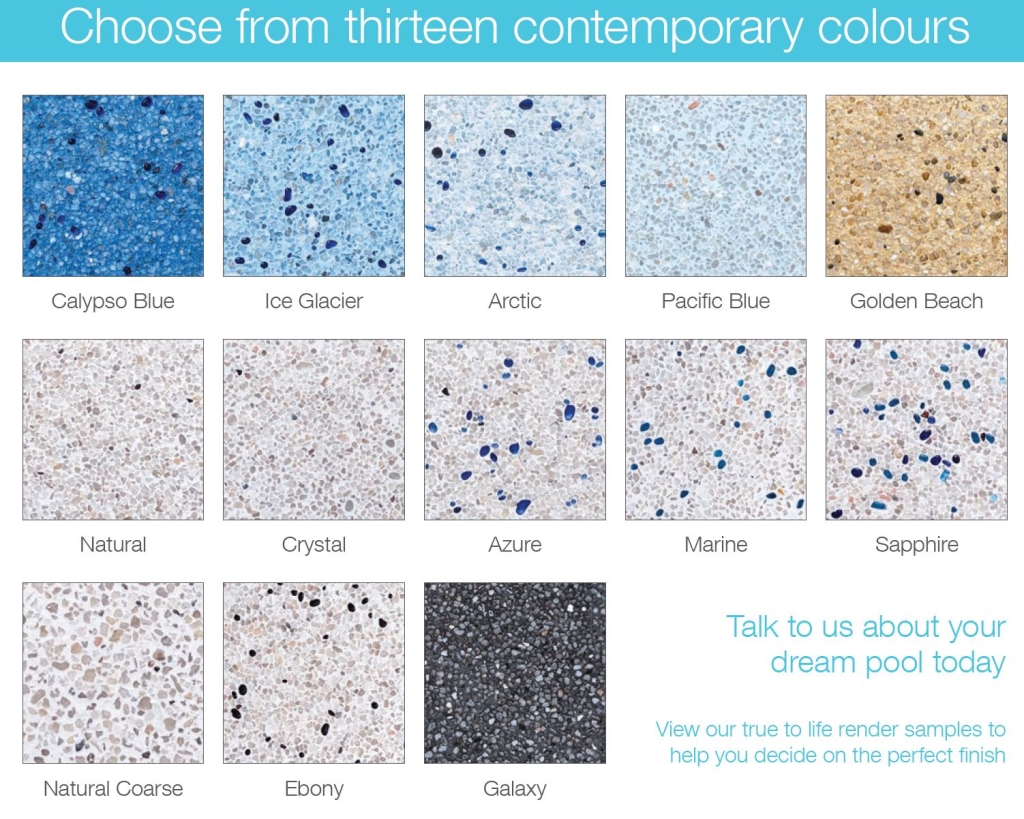

The quality of our existing products has seen a notable improvement. For our customers, the benefits of this new equipment is clear. The better sizing of the end product and the significant reduction in organic materials mean that they can expect a higher quality product with fewer impurities. This translates to reduced maintenance, particularly for applications like pool installations where staining caused by organic materials can be a common issue.

Highest Quality Product for Current and Future Customers

The installation of the classifier represents a significant commitment to quality and customer satisfaction. Our investment in this new technology allows us to produce an improved product that meets the highest standards of cleanliness and consistency.

Contact us for a sample of our newly improved products and see the difference for yourself.

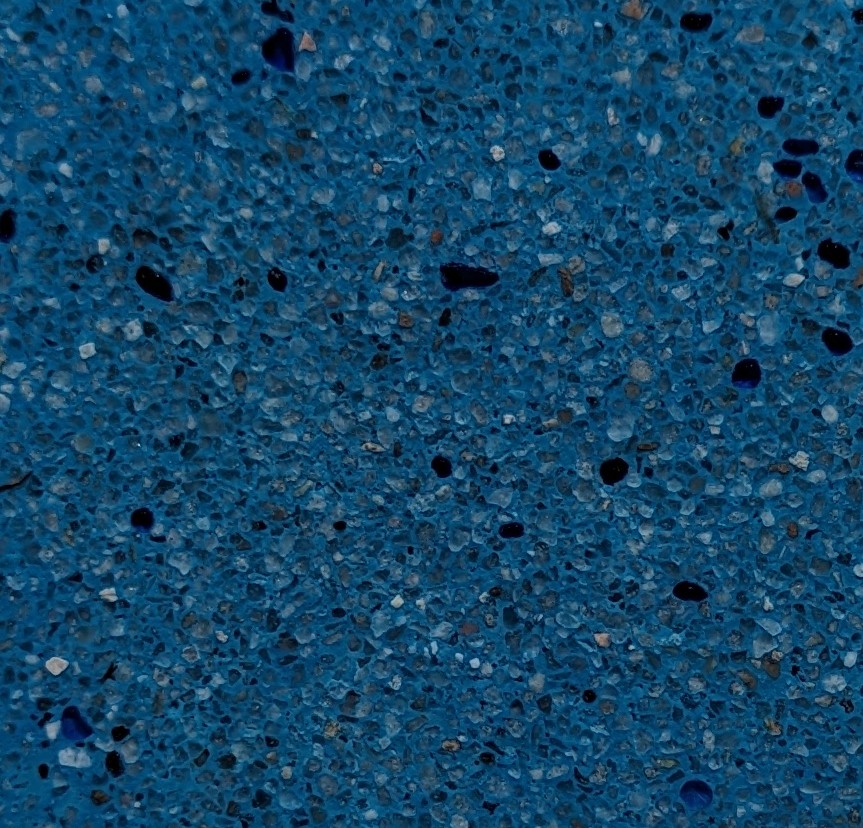

Linatex Fluidised Flat Bottom Classifier. The water is pumped in at high pressure to get the lighter materials (fines and organic matter) to flush over the weir and be removed from the coarser sand particles.

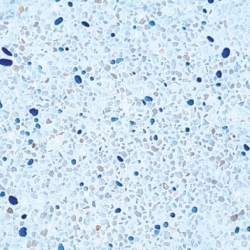

This is the sieve bends that separates and captures the organic material from the light weight material that has been removed from Classifier before sending the sand particles over to the Superfine Sand conveyor.